Electrification of Mining Equipment and Sustainable Mining

Sustainability: Lets try to get some clarity on the terminologies which are often utilized for any kind of the mineral/nature resource mining activities. Sustainability in general has broader meaning but in the context of mining world it largely emphasizes more towards the process & method by which the desired mineral/ore can be extracted without affecting the environment & maintain the ecological balance.

Green Mining: The term is mostly focused on reducing emissions or all other kinds of wastes as by-product to environment in one or another way. Today the internet is full of synonymic terminologies which have the aim of depicting the processes’ ill-impacts in many ways. "Clean mining," "green mining," "eco-friendly mining," etc. etc. are many other words which have same meaning in sustainable context.

Why the term 'sustainable' became popular & since when? The term in use is not very old & in the context of climate and environment became the focal in late 1980s. When the first ozone hole was observed & researchers began to find the possible causes & its mitigation. So the first & foremost reason became popular was of reduction of emissions which were causing the ozone depletion. When it was realized that ozone depletion have other consequences as well the ‘sustainability’ was started more prominently with the exploitation of natural resources of any kind.

Carbon emission & sustainability

The global temperature rise & climate change have created an ultimate push to the industries having very high level of emissions to curb down on their emission & change the way of operation by which emissions are reduced and have low impact on environment & ecology through their operations.

The mining industry, power generation & Carbon Emission

From the point of view of a maintenance engineer from the Open Cast mine it could be somehow concluded that—"No mining operation can be made totally emission less" which could be simply realistic straightforward observation from any kind of mining operation. Once the surface is disturbed from its natural form the particulate gets separated, and blown away by wind and then act as pollutant. The particulate of different sizes gets generated and specifically the ones in the range of 3 to 5 micrometer have serious health issues if inhaled.

Depending upon the type of mining operations, the emission particles differ. Below are some of the well know Indian mining companies along with their minerals they are mining- NLC India (Lignite & Coal Mining, Power Generation), CIL(Coal Mining), BALCO(Bauxite Mining, Power Generation), NMDC (Iron ore and Diamond Mining) etc. and there are many more public and private sector units in exploitations of different resources. The purpose is to make understand there are vast varieties of pollutants on the basis of what is being dug up from the earth.

The Idea of Sustainable Mining through Electric Machines

From the point of view of a Mining Machinery Engineer & along with the close engagement with on-field mining machines its been analyzed that choosing a type of mining machine/machinery is a design & functional-based choice rather than some external auxiliary factors like sustainability or low-emission operation.Taking a very simple example of a Bucket Wheel Excavator Machine(BWE) which can weigh upto 14000 Tons- its practically not feasible to propel & drive its components through IC engines. Rather all components of machine are electro-hydraulic or electro-hydro-mechanical drive train operated.These machines by default since their time of first commissioning they are being powered electrically (the first BWE dates back to 1920s). Almost a century before when the sustainable mining and operations are have become too much in focus.The ‘by-default’ design aspects of the machines are nowadays used by the big mining giants as no-emission operation or sustainable operation since being run by electric motors these machines have no end carbon emissions.

“ I would leave up to the reader if this is really a marketing hoax or their operation is truly emission free”

In a mechanized mine of lignite the typical whole chain of equipment in operation is – BWE/Reclaimer → MTC →Hopper → Conveyor Belts → Tripper car→ Spreader/Stacker

All these equipment are electrified & are having electric motors as prime mover. But even in this analysis, the well-to-wheel emissions, emission from the dumps & mines have not been considered by the companies & machine manufacturers.

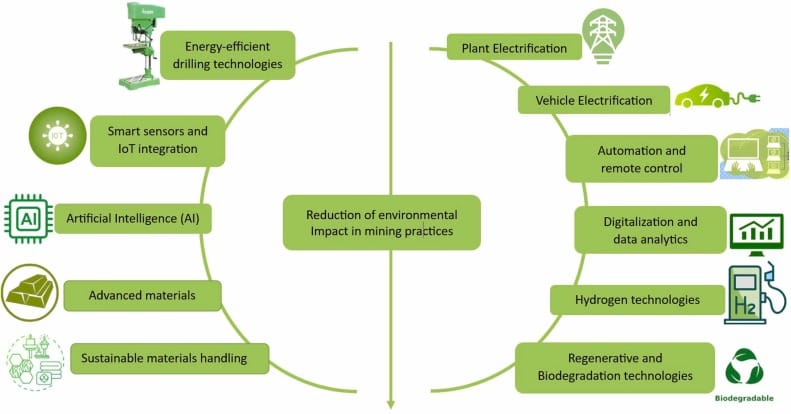

Effective steps in sustainable mining:

It's nearly not possible to extract the earth minerals & resources without creating the disturbance in earth from its natural form. The relevant steps taken at different stages of mining activity help to support the term "sustainable." "Afforestation," "Reclamation," "Ecological parks" etc. which are some of the measures taken by the mining firms to try to balance the negative impact already have been caused through the mining activity. There have never been a full-fledged proof on how these steps & at what stage or duration can fully nullify the effect of mining activity.

All in all, the overall point need to be taken into account that the machines or operation which don’t have any alternate drive can’t be treated as blessing in disguise & claims are made on their sustainable operation just to market their equipment. In all these cases, the electricity utilized to turn these equipment already have been produced with a much bigger scale of carbon emission which already have its consequences before the equipment is in operation